Fittings

Fittings are the mating elements at either end of a flexible shaft. They connect the driving and driven components that the flexible shaft transmits rotary motion between. Fittings come in various sizes and configurations to achieve the required torque transmitting performance of the application. Some of the parameters to take into account when choosing a fitting are:

- Material

- Torque Load

- Endurance Life

- Axial Movement

- Radial Backlash

- Cost

- Custom Design etc.

The following are the most common types of fittings:

Formed Square, On Flexible Shaft

A Formed Square end is created when the ends of a round flexible shaft are mechanically formed into a square shape.

A Formed Square end is created when the ends of a round flexible shaft are mechanically formed into a square shape.

- Pro:

- Most economical

- High torque capacity

- Allows axial movement

- Smallest OD profile

- Con:

- Some radial backlash

- Wear on formed wires

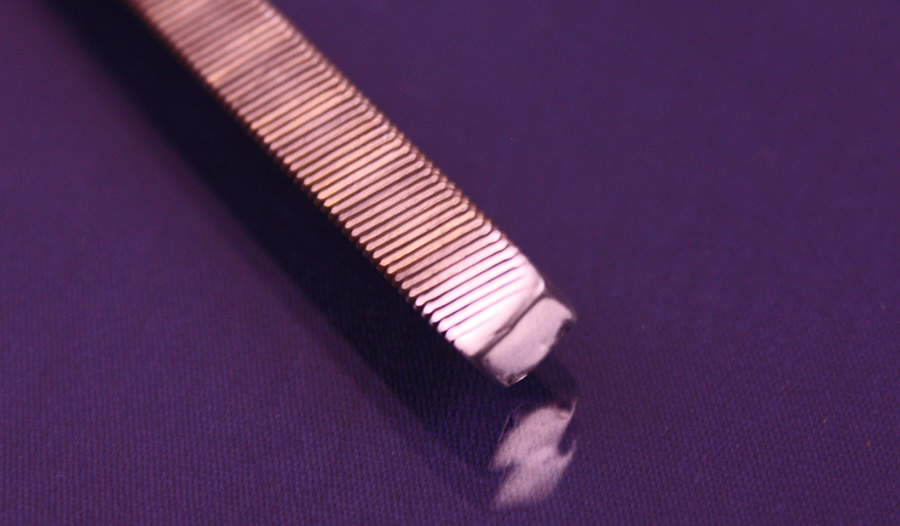

Formed Tube Square, Over Flexible Shaft

A Formed Tube Square is when a close fitting round metal tube is mechanically formed over the round section of a flexible shaft.

A Formed Tube Square is when a close fitting round metal tube is mechanically formed over the round section of a flexible shaft.

- Pro:

- Low wear on formed end

- Economical

- High torque capacity

- Allows axial movement

- Small OD profile

- Con:

- Radial backlash - a few degrees

Round Fitting (female)

Round Female Fittings are made up of a round female hole on one end, which slips over the flexible shaft to be formed, and another round female hole which will interface with the driving or driven device. Typically uses set screws

Round Female Fittings are made up of a round female hole on one end, which slips over the flexible shaft to be formed, and another round female hole which will interface with the driving or driven device. Typically uses set screws

- Pro:

- Moderate Cost

- Moderate torque capacity

- Fits directly to many motor shafts

- Low radial backlash

- Con:

- Large OD profile

- No axial movement of shaft

Round Fitting (male)

Round Male Fittings are made up of a round female hole on one end, which is formed over the flexible shaft, and a round male tip which will unify with the driving or driven device.

Round Male Fittings are made up of a round female hole on one end, which is formed over the flexible shaft, and a round male tip which will unify with the driving or driven device.

- Pro:

- Moderate Cost

- Moderate torque capacity

- Fits directly to many motor shafts

- Low radial backlash

- Con:

- RLarge OD profile

- No axial movement of shaft

Square Fitting (female)

Square Female Fittings are made up of a round female hole on one end, which slips over the flexible shaft to be formed, and a square female hole which will interface with the driving or driven device.

Square Female Fittings are made up of a round female hole on one end, which slips over the flexible shaft to be formed, and a square female hole which will interface with the driving or driven device.

- Pro:

- Allows axial movement

- High torque loads

- Con:

- High cost (less if formed onto fitting)

- Radial backlash - a few degrees

- Some radial backlash

Square Fitting (male)

Square male Fittings are made up of a female round hole on one end, which slips over the flexible shaft to be formed, and a square male tip which will interface with the driving or driven device.

Square male Fittings are made up of a female round hole on one end, which slips over the flexible shaft to be formed, and a square male tip which will interface with the driving or driven device.

- Pro:

- Allows axial movement

- Most commonly used fitting

- High torque loads

- Con:

- Moderate cost

- Some radial backlash

Hex Fitting (female)

Hex Female fittings are made up of a round female hole on one end, which slips over the flexible shaft to be formed, and a hex female hole which will interface with the driving or driven device.

Hex Female fittings are made up of a round female hole on one end, which slips over the flexible shaft to be formed, and a hex female hole which will interface with the driving or driven device.

- Pro:

- Low radial backlash

- Easier installation than a square for radial alignment in many applications

- Allows axial movement

- High/Moderate torque capacity

- Con:

- High cost

Hex Fitting (male)

Hex male fittings are made up of a female round hole on one end, which slips over the flexible shaft to be formed, and a hex male tip which will interface with the driving or driven device.

Hex male fittings are made up of a female round hole on one end, which slips over the flexible shaft to be formed, and a hex male tip which will interface with the driving or driven device.

- Pro:

- Low radial backlash

- Easier installation than a square for radial alignment in many applications

- Allows axial movement

- High/Moderate torque capacity

- Con:

- Moderate cost

Spline Fitting (female)

Splined female fittings are made up of a round female hole on one end, which slips over the flexible shaft to be formed, and a splined female hole which will interface with the driving or driven device.

Splined female fittings are made up of a round female hole on one end, which slips over the flexible shaft to be formed, and a splined female hole which will interface with the driving or driven device.

- Pro:

- Lowest radial backlash

- Highest torque loads

- Easiest installation for radial alignment

- Allows axial movement

- Con:

- Highest cost

Spline Fitting (male)

Splined male fittings are made up of a female round hole on one end, which slips over the flexible shaft to be formed, and a splined male tip which will interface with the driving or driven device.

Splined male fittings are made up of a female round hole on one end, which slips over the flexible shaft to be formed, and a splined male tip which will interface with the driving or driven device.

- Pro:

- Low radial backlash

- Highest torque loads

- Easiest installation for radial alignment

- Allows axial movement

- Con:

- High cost

Panel Mount

Panel mount is a tip designed to fit on a plate in such a way that rotary motion of the shaft assembly is unhindered while axial motion is constrained.

Panel mount is a tip designed to fit on a plate in such a way that rotary motion of the shaft assembly is unhindered while axial motion is constrained.

- Pro:

- Easy installation on a panel

- Con:

- Low speed applications only

- Low torque loads typically

Custom

Custom fittings are available and built to spec. To learn more about our custom options please contact us.

Custom fittings are available and built to spec. To learn more about our custom options please contact us.