Technical Information

About Flexible Shafts

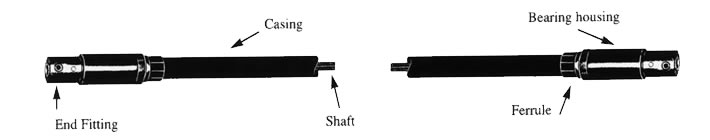

A flexible shaft transmits rotary motion much like a solid steel shaft, but it can be routed over, under, and around obstacles that would make using a solid shaft impractical. A "Flexible Shaft Assembly" consists of a rotating shaft (sometimes called a core) with end fittings for attachment to the driving and driven mating parts. A protective outer casing is used when necessary. This casing has its own fittings, called ferrules, which keep it stationary during use.

A flexible shaft is a highly effective means of transmitting rotary motion and is more efficient than universal joints, gears, sprockets and chains, or belts and pulleys. It is typically lower in cost than these other devices and offers the added benefit of compensating for misalignments in your system that can greatly reduce cost and assembly time.

Typical Flex Shaft Construction

Advantages of a Flex Shaft

- Eliminate alignment problems: Flexible shafts have no need for tight tolerances that solid shafts require.

- Increase design freedom: Infinite possibilities in positioning motor and driven components.

- Higher efficiency: Flexible shafts are 85-95% efficient. Gears, U-Joints, Belts and Pulleys give much lower performance due to greater frictional losses.

- Allow large bending offsets: Flexible shafts permit a full 180 degree off-set while maintaining high efficiency. Flexible couplings only allow 5 degrees of off-set and U-Joints only 30 degrees with up to a 40-50% decrease in efficiency.

- Lower installation cost: Flexible Shafts install in minutes without special tools or skills. Solid Shafts, Gears, Pulleys, and Universal Joints require precise alignment and skilled mechanics for their installations.

- Reduce parts cost: Bearings and housings for Solid Shafts and Gears require precise machining operations. Flexible Shafts eliminate the need for such demanding tolerances and their excessive costs.

- Are not affected by vibrations: Flexible shafts by their very nature are not effected by vibrations.